Focus on Standards

08 August 2017

TECHNICAL REPORT ISO/TR 17844

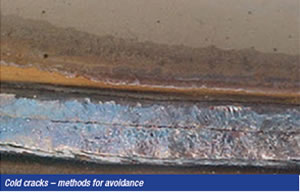

Welding — Comparison of standardised methods for the avoidance of cold cracks

The purpose of this document is to compare currently available methods for determining welding procedures for avoiding hydrogen induced cold cracking during fabrication. This subject has been extensively studied in recent years and many methods of providing guidance on avoidance of cold cracking have been published.

These methods vary considerably in how comprehensively the subject has to be treated. It was considered appropriate to set certain important working criteria for selecting the published methods to be included in this document. In deciding which criteria would be adopted it was agreed that these should include the capabilities for effective use by industry, the end user.

Thus the methods should be able to be used on the basis of traditionally available information and relevant factors. The agreed list of criteria was set to include the following main input parameters:

• steel composition;

• welding heat input;

• joint geometry and material thickness;

• weld hydrogen level;

• preheat

and in addition graphical/computer format of data.

Using the above criteria, the following methods were selected:

• CE (EN 1011-2/ISO/TR 17671-2, C.2-Method A);

• CET (EN 1011-2/ISO/TR 17671-2, C.3-Method B);

• CEN (JIS B 8285);

• Pcm (ANSI/AWS D1.1).

Each method is considered in a separate clause, under the following headings:

• Description of type of test data used to devise the guidelines, e.g. Controlled Thermal Severity (CTS), Y-groove, etc;

• Parent metal composition and range of applicability;

• Material thickness and range of applicability;

• Hydrogen level and welding processes;

• Heat input;

• Other factors/special considerations;

• Determination of preheat (step-by-step example description).

It is important that any calculations using a given method are undertaken using the current edition of the appropriate standard.

Comparison of the different methods

In comparing the methods it is first of all important to recall their origins:

• The CE-method uses a critical hardness approach based on data predominantly from CTS fillet weld testing using mainly carbon manganese steels but including some low alloy steels.

• The CET-method is an empirical approach based mainly on y-groove testing but incorporates some CTS fillet weld data. Steels tested cover both carbon manganese and low alloy types.

• The CEN-method is an empirical approach based predominantly on y-groove test data, many of which come from low alloy steels.

• The Pcm-method includes both a critical hardness approach, and a hydrogen control method. The hardness control method is principally for carbon manganese and some low alloy steels, but

excludes quenched and tempered steels. The hydrogen control approach is said to be for high hardenability, high strength, low alloy steels where hardness control is not practicable.

Parent metal composition range

As can be seen in Table 1, there are some differences in the precise compositional ranges covered, that for the CEN method probably providing the widest coverage.

Joint Geometry

The CE and the Pcm-methods have detailed approaches to providing guidance for fillet welds as well as for butt welds. In certain cases the CE method results in higher preheat temperatures for fillet welds than for butt welds due to the

influence of the combined plate thickness. The Pcm-method allows determination of the preheat temperature for fillet welds of certain steels depending on the hardening in the HAZ. For all the other steels the Pcm-method does not

distinguish between preheating of fillet and butt welds, of the same weld thickness.

Both the CEN – and CET-methods make no fundamental distinction between butt and fillet welds, predicting preheats for butt welds, although some limited guidance on fillet welds is provided by the CET-method.

Plate Thickness

The plate thickness ranges covered are similar for CE, CET and Pcm with an upper limit of 100 mm, while the upper limit for CEN is 200 mm.

Hydrogen levels

For the CEN and CET approaches, hydrogen input is via any value, between 1 ml/100 g and 20ml/100 g for CET and a limit is not defined in CEN. For the CE and Pcm approaches, hydrogen input is via a scale or group covering a range of hydrogen levels.

Heat input

For the CE– and the CEN-method the heat input for no preheating can be determined for butt welds while for fillet welds the parameters can be determined only by the CE– and Pcm-methods. Most of the Pcm-method does not take account of heat input. Thus, full advantage of the benefit of increased heat input in reducing HAZ hardness cannot be used with the Pcm-method, except for the case of fillet welds and no preheat. For butt welds this point is well illustrated when considering for the same plate thickness and heat input for construction steel S355NH, calculating for 25 mm and 3 kJ/mm, the Pcm-method nearly always products the highest preheat when compared to the CE-method- 0°C for CE and 116°C for Pcm.

Depending on the carbon equivalent Figure 1 illustrates the influence of the heat input on the preheat temperature for the CET-method. This is similar to the CEN-method where the heat input up to 4 kJ/mm also influences the preheat temperatures in a certain range depending on the carbon equivalent.

Summary and conclusions

It is clear that there are several distinguishing features to the different methods and these may carry both advantages and disadvantages for the end user, depending on the manner of application. The origins of the different methods should therefore be considered when seeking a method to use with the aim of achieving the best alignment of the practical situation and the original test data when making the selection in the anticipation that this will produce the best prediction.

It is recommended that, whichever method is chosen as providing the best fit to the practical situation, it is used for determining preliminary welding conditions to be subsequently validated by appropriate procedure testing and qualifications.

The user should employ the method that best fits his application. The methods should not prevent an experienced fabricator from using lower preheat temperatures than calculated on the basis of one of the four methods subject to satisfactory practical experience.