Focus on Standards – ISO/TR 581:2005

Weldability – Metallic Materials – General Principles

For many people in the welding industry, the term or concept of weldability has got different meanings. The volume of source material covering the topic, in various degrees of complexity, is also vast and is continuously expanding due to the amount of research being conducted covering welding technology, materials development, asset management, repair and refurbishment and more.

It is thus clear that the term of weldability is flexible and covers the range from the ability to tack two pieces of metal together without having them come apart, to meeting sophisticated needs of highly technical modern requirements for different applications. Weldability is often hard to define quantitatively, so most standards define it qualitatively as shown, for example, in AWS D1.1/D1.1M:2015.

A very general, but widely regarded definition for weldability is that it is a measure of how easy it is to make a weld in a particular parent material, without cracks or other harmful defects, with adequate mechanical properties for service, and resistance to service degradation.

For many practical purposes, the weldability of one material is a comparison with another, where the first material is one that has been welded successfully before. However, to quantify the weldability of a material, a series of tests – each specific to one aspect of weldability – is available. For carbon steels it mostly will focus on testing with regards to the various types of fabrication cracking, like solidification cracking, liquation cracking, hydrogen cracking, lamellar tearing and reheat cracking. Also the material chemical composition can play a large role in determining the susceptibility to certain types of defects and hence the connection of the weldability of a material to a calculated value, using published formulas, likes the Carbon Equivalent (CE) value.

The uncertainty which had arisen in the terminology dealing with weldability, and the complex interaction of the various factors influencing weldability, made it necessary to define general principles related to weldability. ISO/TR 581:2005 is a document that defines these general principles that relate to weldability.

The word ‘Principle’ is defined by the Oxford dictionary as “A fundamental truth or proposition that serves as the foundation for a system of belief or behaviour or for a chain of reasoning.”

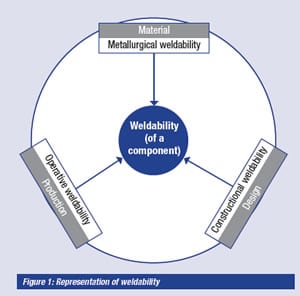

Weldability is defined in this standard as “A component consisting of metallic material is considered to be weldable by a given process when metallic continuity can be obtained by welding using a suitable welding procedure. At the same time, the welds shall comply with the requirements specified in regard to both their metallurgical and mechanical properties and their Influence on the construction of which they form a part.” Thus weldability is governed by three factors namely, material, design and production. Each of these three factors is associated with different properties, like material properties, design properties and production properties.

Metallurgical weldability (Material properties)

Factors that are governed by the material include, but are not limited to the following:

- Chemical composition

- Properties governed by production methods like deoxidation, hot and cold working and heat treatment

- Physical properties like melting point, mechanical strength and toughness

The less these factors have to be taken into account when determining the welding procedure for a certain construction or component, the better is the Metallurgical weldability of a material, within that material group as per ISO 1508.

Constructional weldability (Design properties)

Factors which influence constructional weldability:

- Design of the construction, for example

- Notch effect

- Thickness of the workpiece

- Force distribution

- Conditions regarding loading

- Magnitude and type of stresses in the component

- Temperatures

- Corrosion

- Speed of stressing

The less these factors governed by the design have to be taken into account when selecting the material, the greater the constructional weldability of that specific component or structure.

Operative weldability (Production properties)

Factors which will have an influence include the following:

- Preparation for the welding, for instance the type of joint or shop and field welding

- Welding procedure/s

- Welding process/es

- Welding consumables

- Welding parameters

- Welding positions

- Preheat and interpass temperatures

- Precautions needed for area of production (shop or field welding)

- Pre- and post-treatment

- Post weld heat treatment

- Chemical treatment

- Mechanical treatment

The less the factors governed by the welding procedure have to be taken into account, in developing a fabrication using a specific material, the better the operative weldability of the intended procedure, is.

Conclusion

When constructions or components are being erected or fabricated, the major task is to achieve the load-carrying capacity required for the purpose of use, and to combine this with adequate

security and minimum cost. The weldability of the construction, or of a component, is assured if this is achieved. In order to satisfy this fundamental condition, it is essential to take account of three influencing factors, each of which can be of decisive importance, namely the material, the design and the procedure.