All the 2018 Awards

| Institute Gold Medal Award for 2018

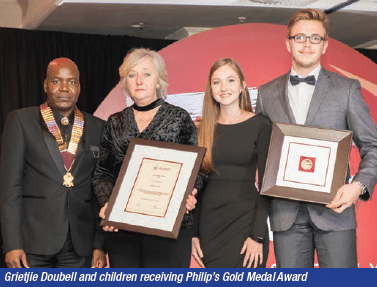

The Institute’s Gold Medal Award, introduced in 1966, is the SAIW’s highest Award and is made to a company or an individual in recognition of outstanding contributions to welding technology or to the Institute. The nominees for the SAIW Gold Medal Award were: Babcock Matla. The nomination was for Babcock Matla’s exceptional delivery of quality and efficiency. Over the years Babcock Matla has explored multiple avenues to facilitate optimal customer satisfaction. These avenues have included, inter alia, technical studies and internal system adaptations. The innovations included strategic pre-heat methods, a conversion from traditional 2% thoriated tungsten to 2% ceriated tungsten electrodes, review of internal systems to include detailed analysis of all weld repairs by both welders and welding supervisors. These initiatives resulted in the weld repair rate decreasing from 7.2% to 2.5% in their last financial year. In the last General Outage of Unit 1 at the power station, 10 000 butt welds were completed with a variety of materials with old to new connections, a weld repair rate of 1.7% was achieved for all welds done in the boiler – a phenomenal achievement. Philip Doubell. The late Philip Doubell was a dedicated contributor to the welding industry making many valuable technical contributions and providing inspiration and mentorship to all those who crossed his path. A key focus of Philip’s work at Eskom was life extension of plants with varying welding technologies and he achieved notable successes at Koeberg Nuclear Power Station and the Hendrina Power Station. Philip worked closely with Prof Danie Hattingh and was a co-inventor of the WeldCore technology. To a large degree it was his inspiration and dedication that ensured the success of the project, particularly the industrial application and commercial readiness of the WeldCore technology. Philip made valuable contributions to the industry at large and particularly to Eskom, his employer by publishing and presenting many technical papers. He is cited as publishing 22 research papers on ResearchGate having co-authored many papers with leading international academics as well as industry stalwarts. Philip would also gladly present his research work and technical papers at SAIW conferences and technical evening meetings and was awarded the Harvey Shacklock Gold Medal Award in 2006 for his paper titled “Weld refurbishment of heavy walled components, hydro-penstock repair”. Philip lead the way in the founding of the International Welding Engineer qualification programme which was initially offered by the University of the Witwatersrand, and was part of the first group to be trained on this qualification programme. For 2018 the Award was given posthumously to Philip Doubell in “recognition of his dedication as a Welding Engineer, who inspired and developed welding technologies, which made significant contributions to the industry at large.” Philip’s wife Grietjie, accompanied by their son and daughter, received the Award on Philip’s behalf.

|

| SAIW PRESIDENTS’ AWARD FOR NDT

Most people will not appreciate that SAIW has been training NDT personnel for more than 40 years – the same period of time that SAIW has offered training in welding. NDT is a very important part of the Institute’s programmes and we want to encourage more young people to enter this field which offers good career opportunities. The SAIW Presidents’ Award recognises the top NDT student on Institute courses and is made in the name of the past Presidents of SAIW who have helped guide the Institute to not only become a vital part of the local welding industry but also to be South Africa’s reference point for high quality training in welding and NDT training. This year, the SAIW Certification Governing Board gave this Award to two recipients: Bronwyn Nadene Geel (for achieving distinctions in Magnetic Testing Levels 1 and 2; Penetrant Testing Levels 1 and 2; Visual Testing Level 1; Ultrasonic Wall thickness Testing, Ultrasonic Testing Level 1 and Radiographic Interpreters Level 2. To emphasise Bronwyn’s achievement, during the initial examination for Ultrasonic Level 1 she achieved an average of 88% and in Radiographic Interpreters, which is the most difficult method to pass, she achieved an overall average of 91% during the initial examination.

|

|

Collen Morithinyana Tseke (for achieving distinctions in Magnetic Testing Levels 1 and 2; Penetrant Testing Levels 1 and 2; Visual Testing Level 1; Ultrasonic Wall thickness Testing, Ultrasonic Testing Level 1 and Radiographic Interpreters Level 2.To emphasise Collen’s achievement, during the initial examination for Ultrasonic Level 1 he achieved an average of 92% and in Radiographic Interpreters, which is the most difficult method to pass, he achieved an overall average of 82% during the initial examination.

|

|

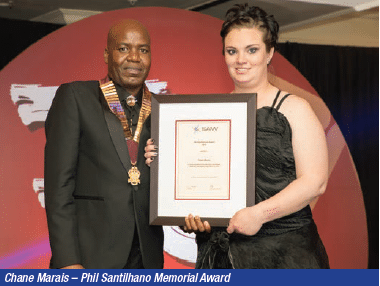

Phil Santilhano Memorial Award The Phil Santilhano Award, which is presented to the best student on the Institute’s courses in Welding Supervision and Inspection, is named after the man who was one of South Africa’s leading welding technologists and is best remembered for the ground-breaking work he did whilst employed by Vecor on Submerged Arc and Electro-Slag welding of heavy wall pressure vessels. Santilhano became the Institute’s first full time employee when he was appointed Technical Director in 1977. This year’s winner was Chane Marais who achieved the highest mark for the SAIW Welding Inspectors Level 2 programme.

|

|

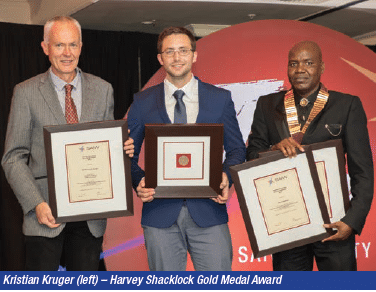

Harvey Shacklock Gold Medal Award The Harvey Shacklock Gold Medal Award is made to the author of the best technical paper presented at an Institute or IIW event. Harvey Shacklock was the Managing Director of BOC (British Oxygen Company) now known as Afrox. He was instrumental in founding the Southern African Institute of Welding and was the President when it was founded on 1st March 1948, 70 years ago. This Award was named in memory of his contribution to the welding industry and it was first presented in 1949. Afrox, part of the worldwide Linde group, generously donates a gold medal for the Award. This year’s Award went to Kristian Kruger for his presentation “Cold repair of Inconel 625 clad layer on medium carbon high strength steel”. The paper was co-authored by Frederic Laurent of 3C Metal and Pieter Pistorius from the University of Pretoria – both of whom received certificates in acknowledgement of their participation in the paper which was presented at the International Institute of Welding Annual Assembly Commission 2 in Indonesia (Bali) in 2018.

|

Best IIW Manufacturing Certification Company AwardThis Award, introduced for the first time this year, is made in recognition of a company that has excelled in the ISO 3834 Certification Manufacturing scheme by demonstrating excellence in the implementation of a welding process control system. The nominees for this Award were: Actom John Thompson is a leading designer and manufacturer of industrial boilers and associated plant whose name is synonymous with well-engineered boilers. As well as related products incorporating heat transfer technology, Actom also designs, supplies, installs and retrofits new and existing environmental equipment and provides boiler service and maintenance for Eskom’s coal-fired power stations. Aveng Grinaker-LTA Mechanical and Electrical is a market leader in providing fabrication, construction and maintenance services for process plants in the oil & gas, petrochemicals, minerals processing, desalination, renewable energy, chemicals, steam generation, power and allied industries. Specialist divisions within the group provide services for capital projects, turnarounds, shutdowns, and plant maintenance. Gascon is a manufacturer of pressure vessels for the petro-chemical, power generation and off-shore industries as well as storage vessels for the transport industry. The company has an impressive range of certifications in addition to the ISO 3834 which includes the ASME U and R stamps, National Board, Chinese SELO certification, DNV Pressure Vessel Certification, European Pressure Equipment certification to PD 5500, EN 13485 and EN 13530 as well as European Road and Rail for Dangerous Goods Certification. Hi-Tech Pressure Engineering designs and manufactures code compliant pressure equipment and related plant with customers in a wide range of industries. Products include storage and process vessels, as well as piping systems that qualify as pressure equipment. Kelvion Thermal Solutions services a wide range of industries specialising in the manufacture of heat exchangers, pressure vessels and process equipment. Kelvion has extensive knowledge and Vessel Fabrication specializes in the manufacture of pressure vessels, storage vessels, shell & tube heat exchangers which are used throughout South Africa and abroad in a number of industry sectors including mining, precious metals & base metals, refineries, petrochemical, food & beverage, defence & munitions, water treatment & purification and the cosmetics industry. This year’s winner was Kelvion Thermal Solutions.

|

|

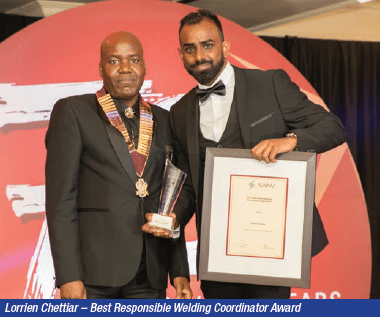

Best Responsible Welding Coordinator Award This Award, also introduced for the first time this year, is made in recognition of an exceptional welding Coordinator for the IIW Manufacturing Scheme responsible for the implementation and maintenance of the welding processes and the welding quality mangement. The nominees for this Award were:

|